SCRAP YARD

OUR SOLUTIONS

- Overhead crane beam

- Intermediate beam

- Scrap loading basket (with standard or automatic opening)

- Transfer car

CLESID LORBER

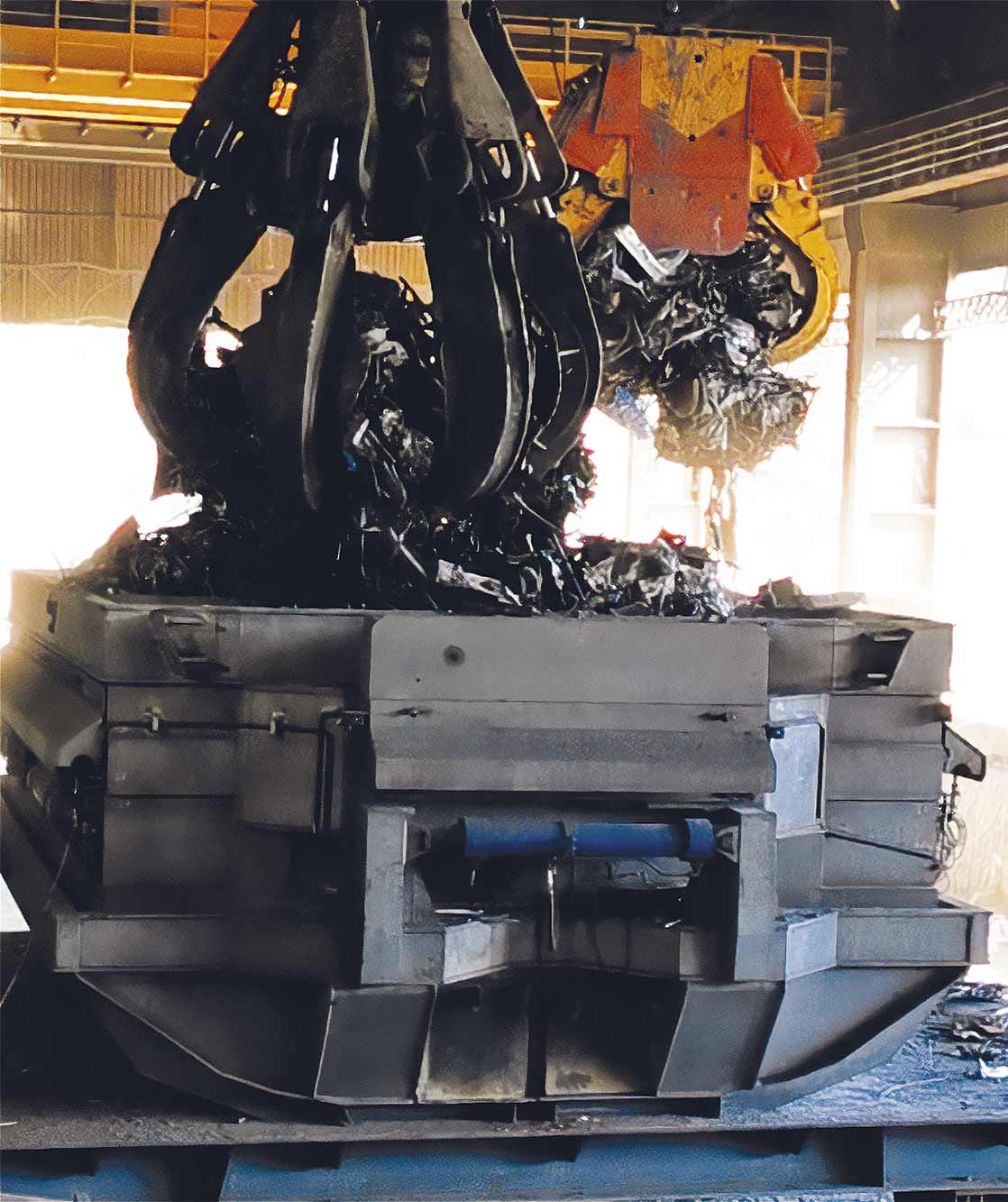

Scrap loading basket

EQUIPMENT :

40t Hydraulic Opening Rectangular Scrap Loading Basket

STUDY CONTEXT :

Need to maneuver the opening of the basket above a scrap metal preheating container by the crane operator.

SOLUTION REALIZED :

Embedded and autonomous hydraulic group with opening controlled by radio control.

EQUIPMENT :

20t Hydraulic Opening Round Scrap Loading Basket

STUDY CONTEXT :

Need to maneuver the opening of the basket

above the oven by the auxiliary hook of the overhead crane.

SOLUTION REALIZED :

Basket shells actuated by cables via an auxiliary beam.

CLESID LORBER

Overhead beam

EQUIPMENT :

Bridge lifting beam for transporting scrap loading basket – WLL 170t

STUDY CONTEXT :

Design as part of a change of scrap loading basket of different dimensions from the existing one following the addition of scrap preheating equipment.

SOLUTION REALIZED :

Embedded and autonomous hydraulic group with opening controlled by radio control.

EQUIPMENT :

Pilot arc furnace shell transport beam – WLL 11t

STUDY CONTEXT :

Need to transport a complete furnace shell with refractory to a repair area

SOLUTION REALIZED :

Handling beam with 4 lifting chains

Transfer car

Depending on the configuration of the steelwork’s halls, it is very often necessary to install transfer cars to drive the loading baskets from the scrap yard to the furnace hall.

We offer all types of transfer car for baskets according to customer specifications by integrating all the safety devices allowing it to evolve in a constrained environment while preserving the safety of its operators.

EQUIPMENT :

Transfer cart for scrap loading basket – Transportable mass approx. 80t

STUDY CONTEXT :

Replacement of the existing transfer car for use of a new loading basket for scrap transfer between the loading area and the furnace hall

SOLUTION REALIZED :

Transfer car on motorized rail/roller with safety devices

EQUIPMENT :

Foundry (France)6t Hydraulic opening round scrap loading basket

STUDY CONTEXT :

Need to maneuver the opening of the basket in the absence of an auxiliary hook on the overhead crane.

SOLUTION REALIZED :

Embedded and autonomous hydraulic group with opening controlled by radio control.